1. Once the size of the final die is set via the PLC, the die specifications will be fully automatically displayed on the monitor.

2. The driving motors of the drawing unit and the final capstan will be synchronously controlled to achieve a drawing slip ratio of less than 2%.

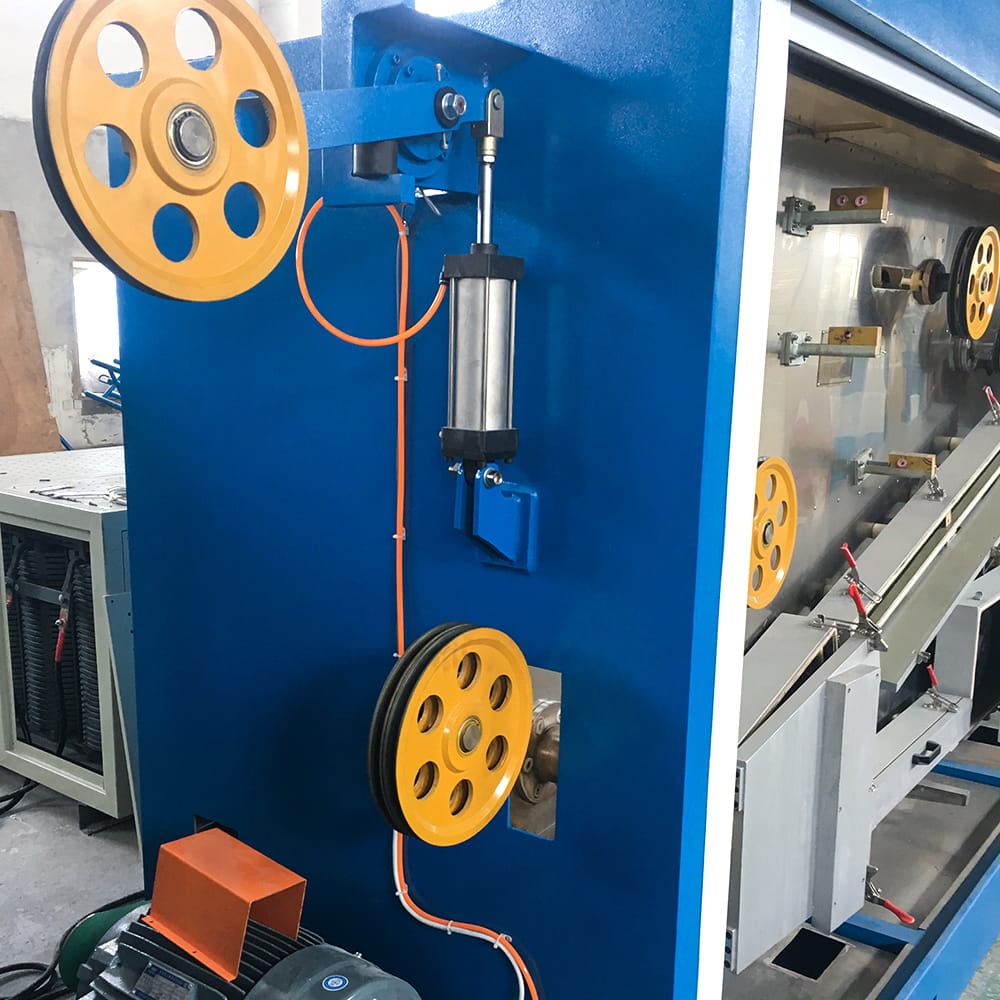

3. The rapid die-change system allows for changing only the final die during operation instead of all the dies, which saves a significant amount of time.

| Model: | 450-13DT |

| Inlet diameter: | Φ8.0mm |

| Outlet diameter: | Ф1.6-3.5mm |

| Max. annealing speed: | 800m/min |

| Usage: | bare copper wire drawing |

| Drawing pass: | 13 |

| Diameter of drum: | Φ450mm |

| Total noise: | <80db |

| Main machine power: | 160KW |

| Annealing machine: | 11KW |

| Take-up machine: | 15KW |

| Power: | 380V 50HZ or others |

| Method of speed governing: | Frequency converter control |

| Capacity of take-up: | 500KGS |

| Pay-off method: | over-head type |

| Lubrication method: | half-immersing + spray type |

中文简体

中文简体 русский

русский Español

Español عربى

عربى