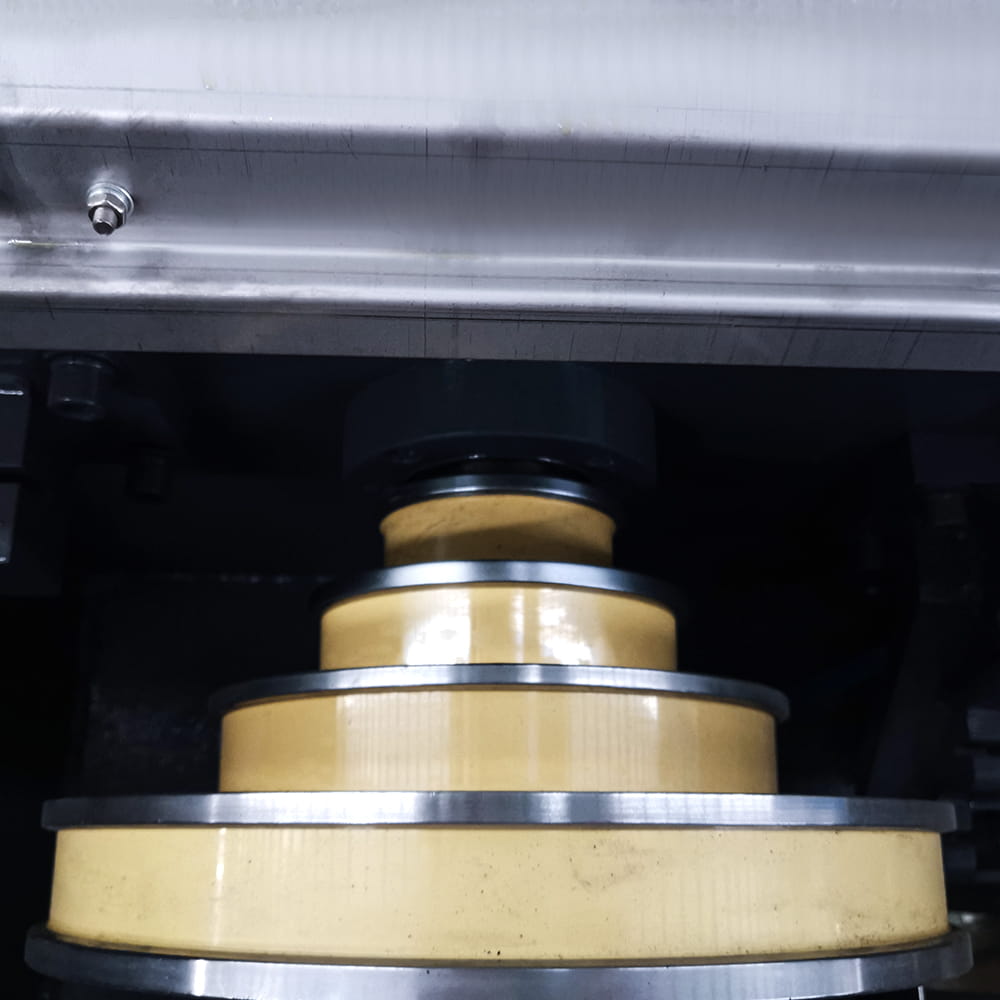

1. Precision grinding technology is adopted to ensure high meshing accuracy, low noise, and easy shifting between high and low gears.

2. With the fully immersed lubrication-cooling method, after undergoing sufficient cooling and lubrication, not only can an excellent wire surface be obtained, but also the service life of the drawing die can be extended.

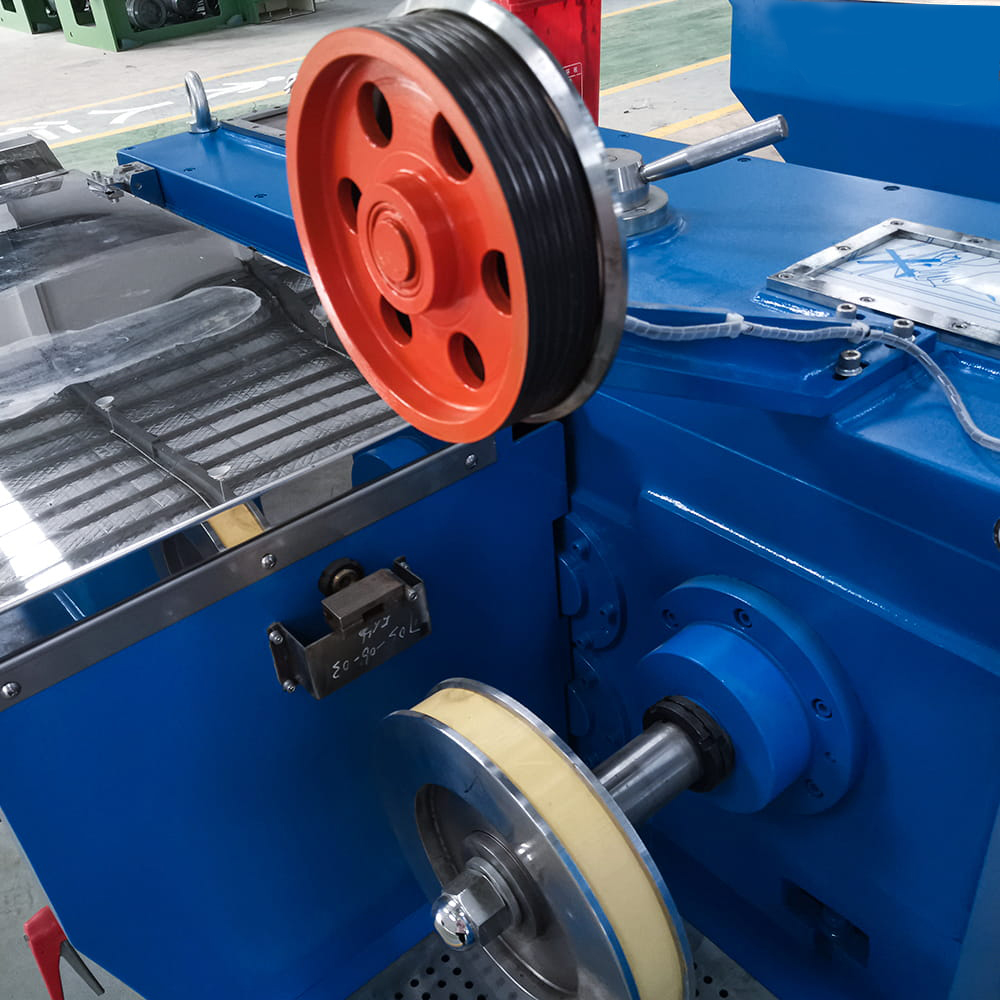

3. The wire-drawing wheel and constant-speed wheel are treated by tungsten carbide spraying.

4. The machine operates stably and silently.

5. It is characterized by high speed, energy-saving, space-saving, and manpower-saving features.

| Model: | 9DS |

| Usage: | Bare copper wire drawing |

| Inlet diameter: | Ф3.0mm |

| Outlet diameter: | Ф1.0-1.6mm |

| Quantity of drawing dies: | 9 |

| Slip ratio of main machine: | 18.50% |

| Slip ratio of last die: | 15.50% |

| Correction system: | Automatically control |

| Max. Drawing speed: | 1500m/min |

| Using motor/ main motor: | 45KW AC |

| Dynamic control: | Double frequency converters control |

| Operation direction: | Right hand machine |

| (from Left to right) | |

| Colour: | As customer's need |

| Brand: | Liqiang or OEM |

| Voltage: | 380V or Customized |

| Brake: | Pneumatic brake |

中文简体

中文简体 русский

русский Español

Español عربى

عربى