1. The machine is capable of drawing double wires and annealing simultaneously, which significantly enhances its efficiency.

2. It features dual drives and motors for take-up control. The drawing process is stable, with independent tension control, making the wires less prone to breakage.

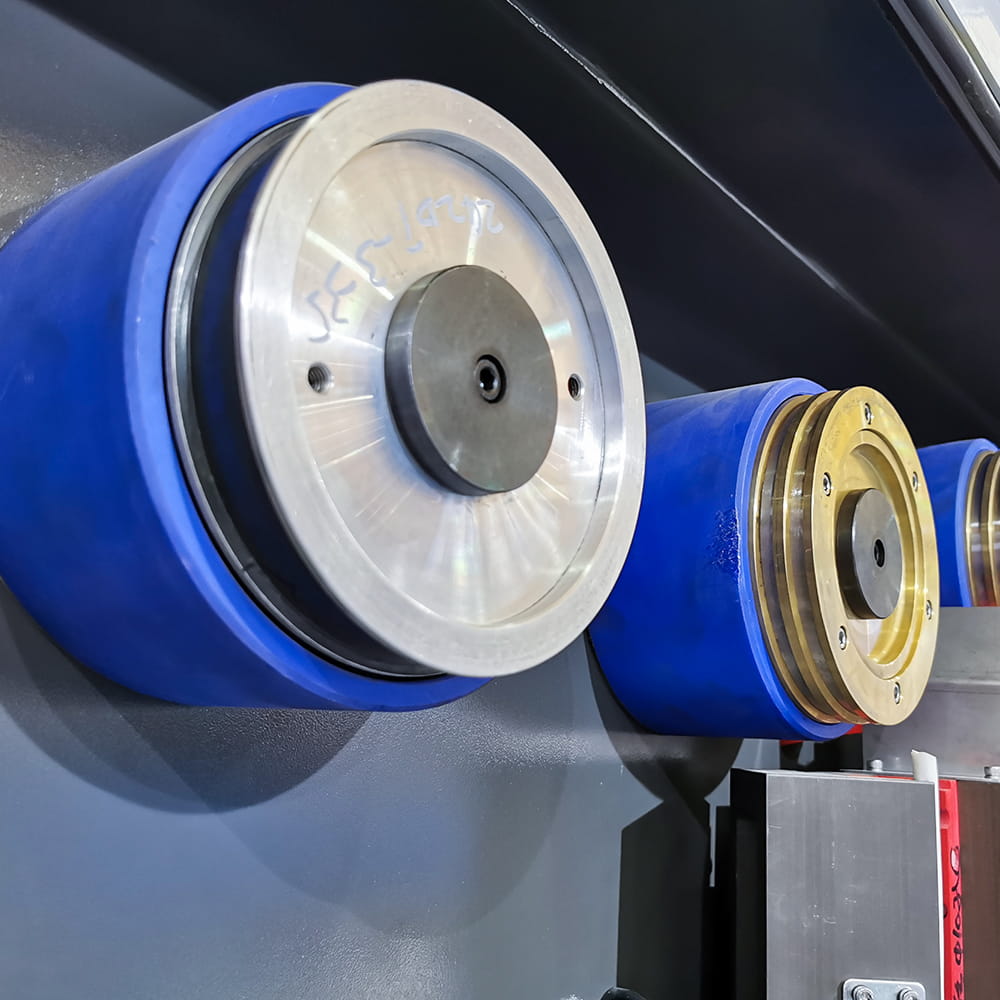

3. Spray ceramic wire pulleys are employed, with 4 in each of the 11 layers and 1 in the final layer, arranged horizontally to facilitate more convenient wire threading.

4. The compact machine body design maximizes the space for guiding operations. The cover in the pull drum area is a sealed stainless-steel door cover that can be manually opened, presenting a beautiful and elegant appearance.

| Model: | 24-2DT |

| Inlet diameter: | 2X1.0mm-1.6mm |

| Outlet diameter: | 2X0.19mm-0.5mm |

| Quantity of drawing dies: | 24 |

| Slip ratio of main machine: | 16% |

| Slip ratio of last die: | 8% |

| Max. Drawing speed: | 2000m/min |

| Using motor/ main motor: | 30kw |

| Usage: | Bare copper wire drawing |

| Correction system: | Automatically control |

| Annealing method: | DC three section annealing |

| Voltage: | 380V or Customized |

| Brake: | Pneumatic brake |

| Operation direction: | Right hand machine |

| Colour: | As customer's need |

| Brand: | Liqiang or OEM |

中文简体

中文简体 русский

русский Español

Español عربى

عربى