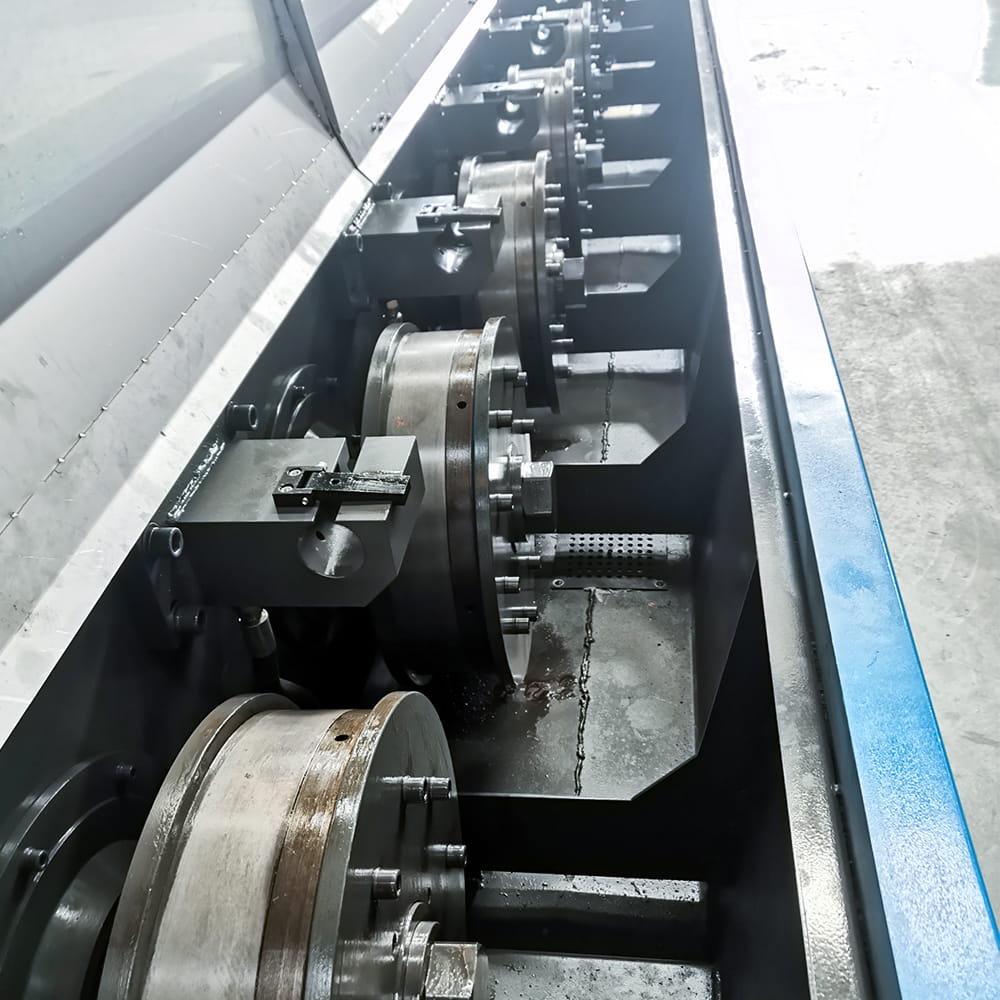

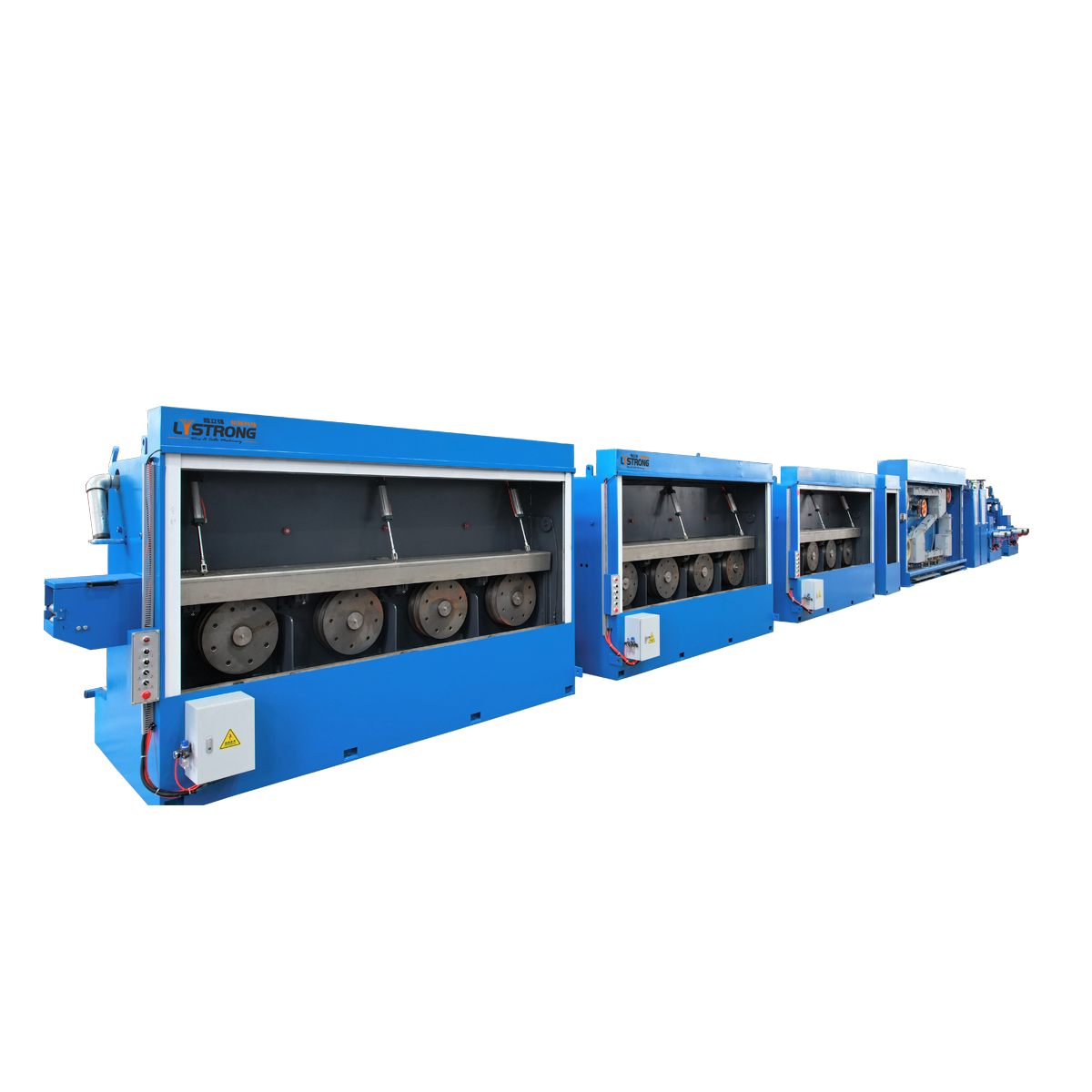

1. The main gearbox body is a one-piece casting, high-precision hard-tooth surface helical gear transmission (the tooth surface is formed by a German grinding machine), the cable fuel tank cover is sealed with a double-layer cover, and the equipment is beautiful in appearance. Advanced structure, low operating noise, high production efficiency, and high economic benefits;

2. The drawing capstan is sprayed with tungsten carbide treatment, which has good wear resistance and long life; the drawing part is semi-immersed cooling, the drawing die and copper wire can be optimally cooled and lubricated, which can effectively extend the use of the drawing die and capstan life;

3. There is a space between the capstan box and the gearbox. In order to prevent the drawing fluid and the gearbox oil from interpenetrating and mixing, multiple seals are adopted in the design and assembly to prevent penetration;

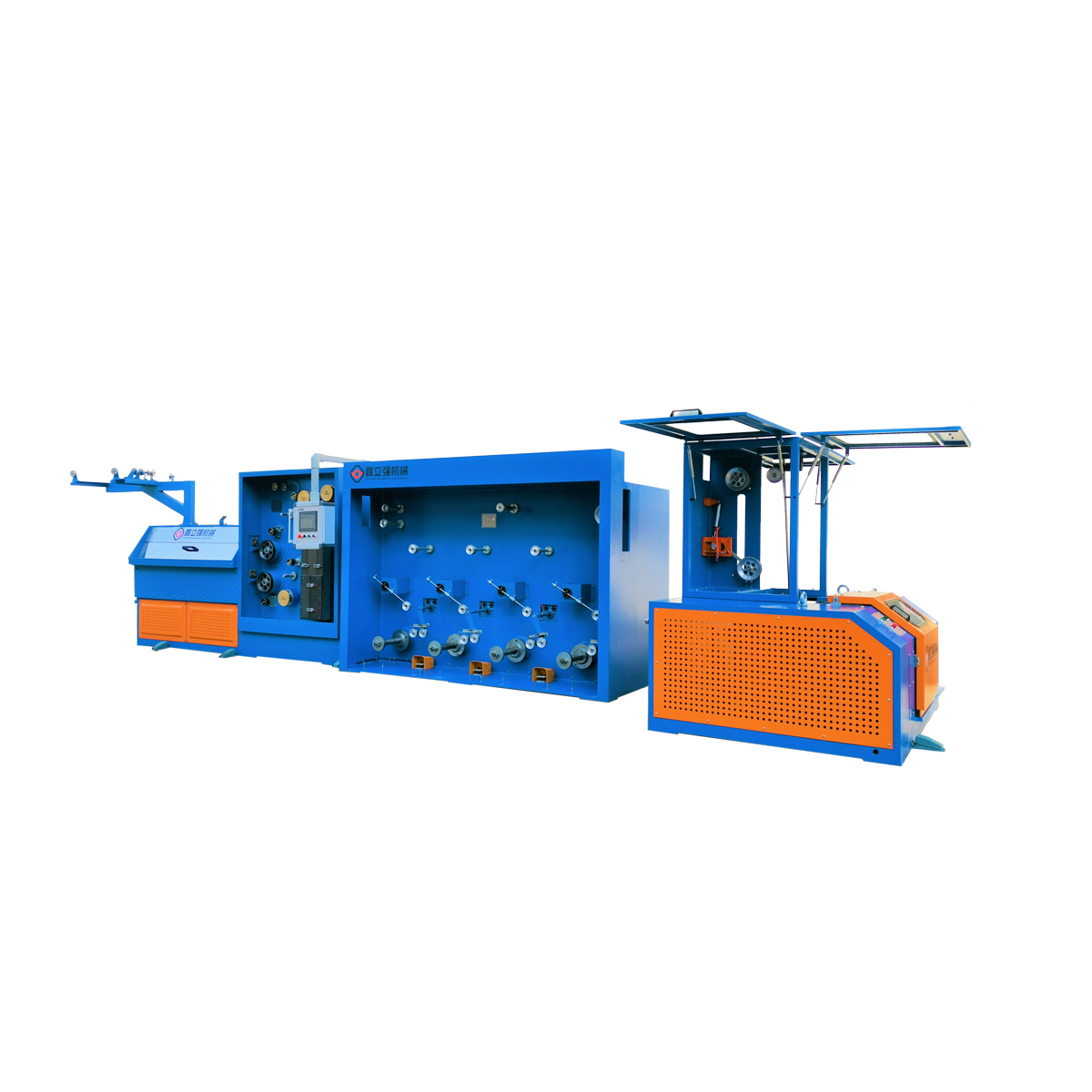

4. The equipment adopts a plum-blossom take-up machine to take up the wire, which has the function of frame changing without stopping, and has good production continuity;

5. The whole machine adopts PLC, frequency conversion speed control, synchronously adjustable speed, and automatic shutdown functions such as disconnection and failure.

| Model: | LHD400-7D |

| Inlet diameter: | Φ8.0mm |

| Outlet diameter: | Φ2.6mm-Φ3.0mm |

| Max. annealing speed: | 15m/s |

| Speed ratio of capstan: | 1.38-1.20 |

| Drawing pass: | 7 |

| Diameter of drum: | Φ400mm |

| Total noise: | <80db |

| Certification: | ISO |

| Condition: | New |

| Voltage: | 380V or Customized |

| Brand: | Liqiang or OEM |

| Bearing: | NSK |

| Color: | as Requirement |

| Debugging: | Before Delivery |

| Delivery Time: | 30-60 Days |

| Transport Package: | Wrapped with Plastic |

| HS Code: | 8463300000 |

中文简体

中文简体 русский

русский Español

Español عربى

عربى