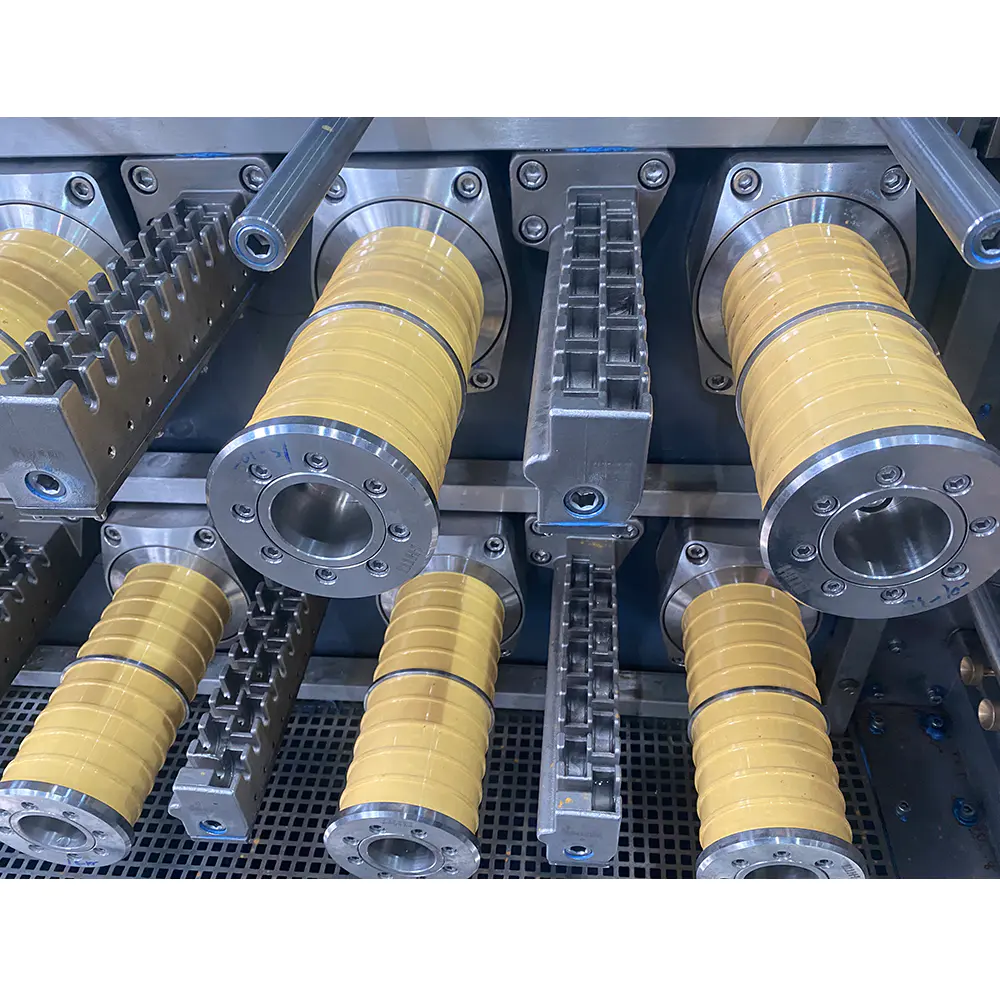

1. Rapid mold changing system; Can produce finished wires of different diameters without the need to replace the entire wire drawing mold

2. Cooling and lubrication system: The drawing tower wheel area adopts a strong spray type, and the drawing die is lubricated by pressure through the eye die seat to ensure stable pressure and lubrication effect of the spray oil supply

3. Main shaft bearings: German FAG series or imported Swedish SKF or equivalent brand

4. Annealing control: The annealing voltage coefficient can be set on the operation panel, and the equipment can automatically control according to the annealing coefficient and production line speed; Ensure the stability of annealing voltage and current and synchronization with production line speed.

5. Wiring method: single line guidance for the entire machine; When threading, the annealing cover and cooling area cover can be opened, which can ensure that 20 wires are always parallel during the production process prevent tangling.

|

Type |

DT100.140.8-25 |

DT120.200.14-19 |

DT100.140.16-25 |

|

No.of wire |

8 |

14 |

16 |

|

Inlet dia.(mm) |

1.4-1.8 |

Max.2.6 |

1.5-1.8 |

|

Outlet dia.(mm) |

0.12-0.64 |

0.25-0.64 |

0.12-0.4 |

|

Max.speed(mpm) |

1800 |

1800 |

1800 |

|

Max.dies |

25 |

19 |

25 |

|

Main motor(kw) |

110KW+37KW |

85KW+200KW+55KW |

180KW+45KW |

|

Draw wheel(mm) |

100 |

120 |

100 |

|

Annealing control |

DC |

||

|

Contact wheel dia.(mm) |

140 |

200 |

140 |

|

Annealing voltage (V) |

60V |

||

|

Annealing current (A) |

2000 |

5000 |

2000 |

|

Type |

DT120.200.16-19 |

DT120.200.20-19 |

DT100.200.24-25 |

|

No.of wire |

16 |

20 |

24 |

|

Inlet dia.(mm) |

1.8-2.6 |

1.8-2.6 |

1.8-2.0 |

|

Outlet dia.(mm) |

0.25-0.80 |

0.2-0.64 |

1.5-0.4 |

|

Max.speed(mpm) |

1800 |

1800 |

1800 |

|

Max.dies |

19 |

19 |

25 |

|

Main motor(kw) |

85KW+200KW+55KW |

110KW+200KW+75KW |

85KW+250KW+55KW |

|

Draw wheel(mm) |

120 |

120 |

100 |

|

Annealing control |

DC |

||

|

Contact wheel dia.(mm) |

200 |

200 |

200 |

|

Annealing voltage (V) |

60V |

||

|

Annealing current (A) |

5000 |

6000 |

5000 |

中文简体

中文简体 русский

русский Español

Español عربى

عربى