1. Equipped with an individual motor, it allows for easy control of the elongation and is simple to operate.

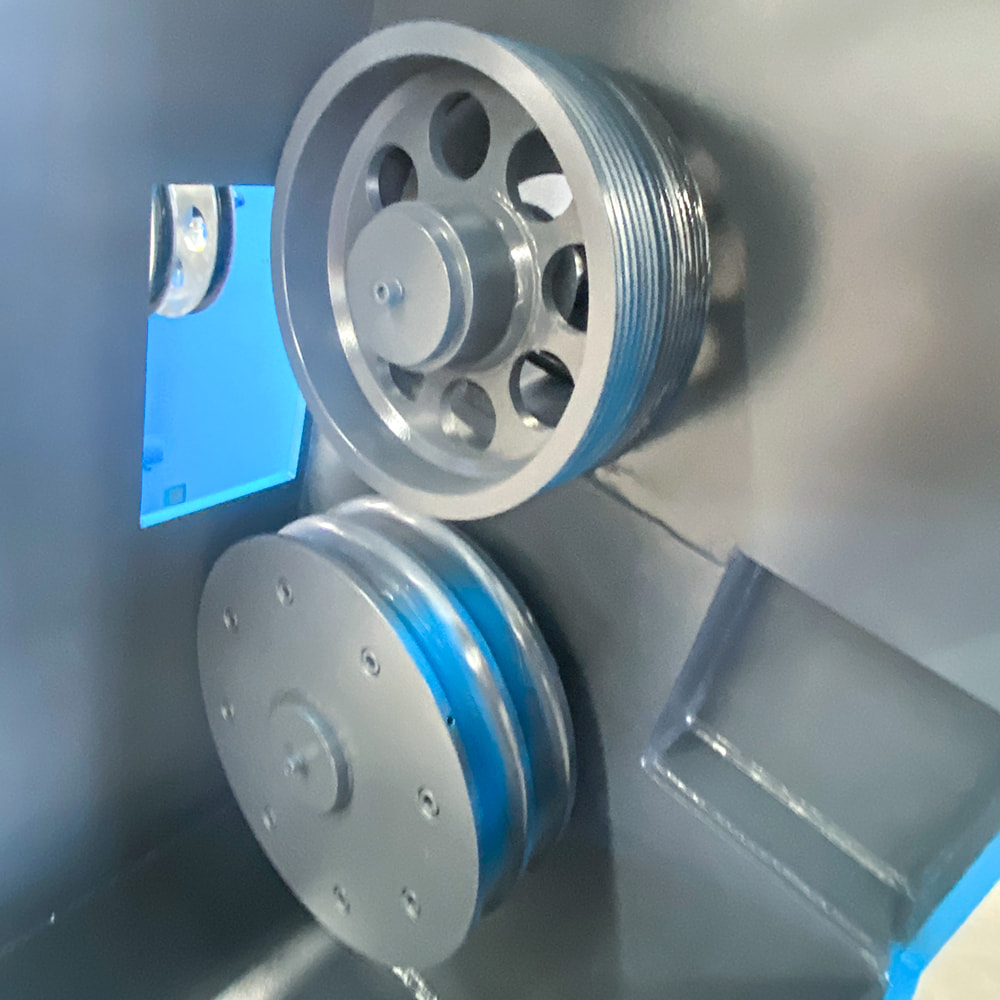

2. Featuring an independently-driven drum, it enables non-sliding wire drawing with less dust generation.

3. The high-speed precision gear ensures a longer service life while generating lower noise.

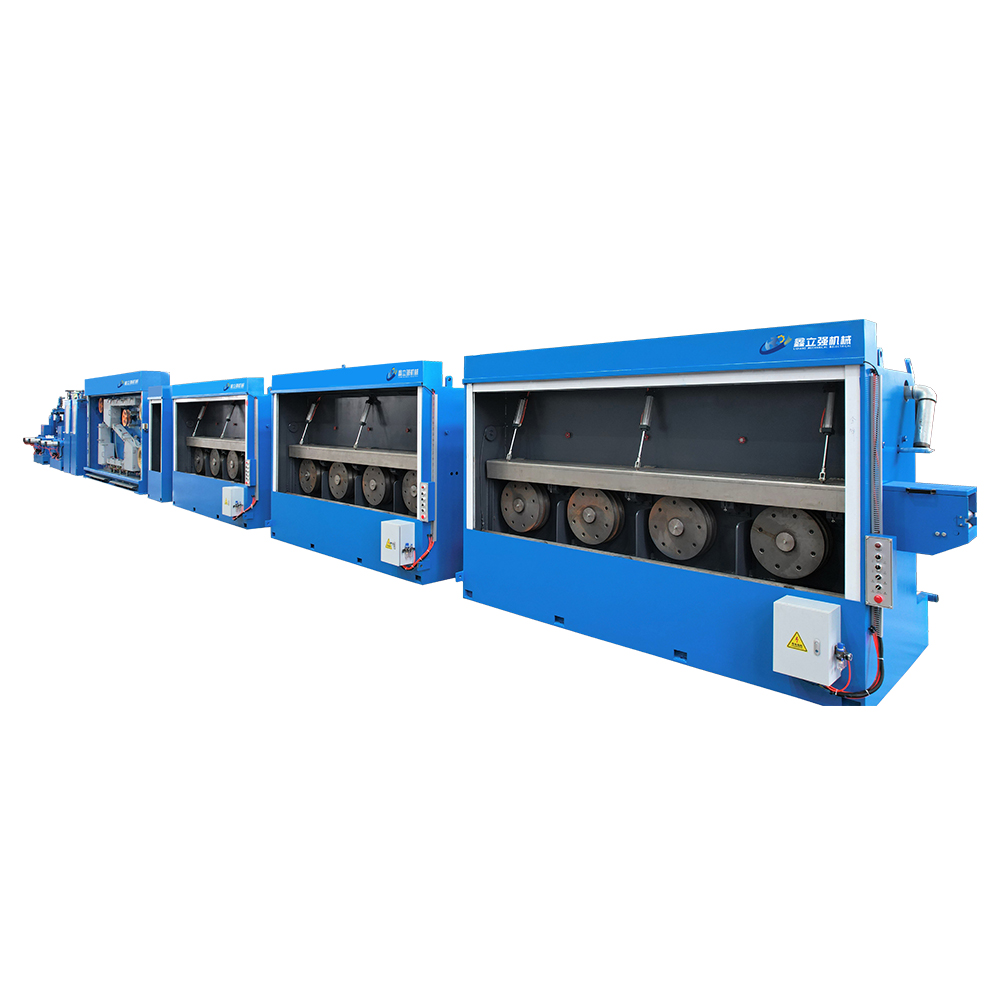

4. The horizontal structure makes the operation much easier.

5. Temperature control guarantees the safety of the production process.

6. The Siemens driver and touch screen make parameter setting more convenient.

| Model: | 450/13-2DT |

| Inlet diameter: | 2*Φ8.0mm or 1*Φ8.0mm |

| Outlet diameter: | Φ1.6 mm ~Φ4.0mm |

| /Φ1.2 mm ~Φ4.5mm | |

| Max. annealing speed: | 25m/s |

| Die size: | Φ45*30mm |

| Drawing pass: | 13 |

| Diameter of drum: | Φ450mm |

| Drawing motor: | 75KW*12+60KW*1 |

| Annealing wheel diameter: | 450mm |

| Annealing motor: | 30KW independent motor drive |

| Annealing voltage: | AC55V |

| Annealing current: | AC8000A |

| Annealing power: | 810KVA |

| Elongation: | 25%-35% |

| Storage wire quantity: | 9m |

| Total noise: | 80db |

中文简体

中文简体 русский

русский Español

Español عربى

عربى