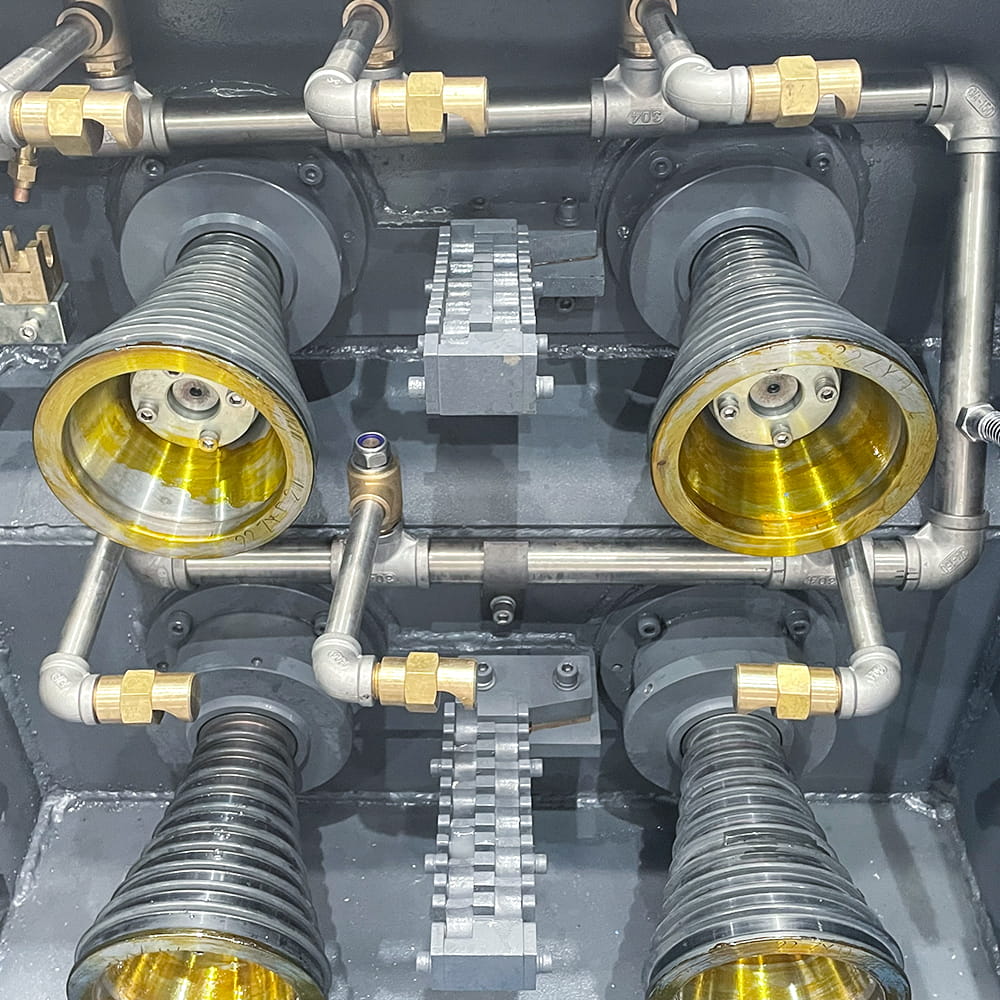

1. The machine is crafted through one-piece casting. Subsequently, it undergoes annealing to relieve internal stress. After that, it is precision-milled to create a single-strand hole, resulting in a highly refined finish.

2. Accuracy: The axle center is treated to an HBS220 - 250 hardness level. This treatment effectively eliminates internal stress and enhances the workpiece's rigidity. Coordination parts are ground meticulously to guarantee the balance of concentricity and achieve true roundness.

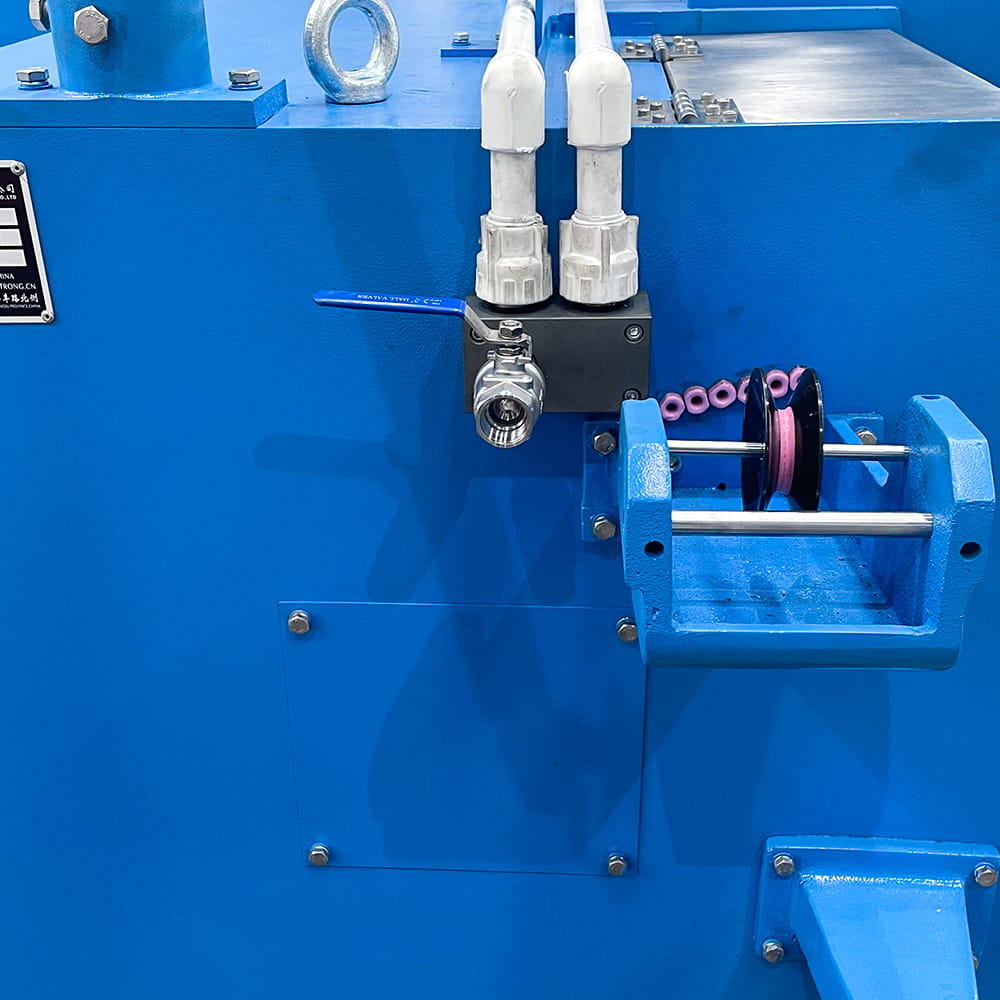

3. The stretching wheel's loading and unloading mechanism employs conical pressing for fixation. It can be adjusted and secured in relation to the position of the eye mold. This method is simple for loading and unloading operations and ensures that the precision of the axle center remains intact.

4. For the lubrication of the stretching wheel and the stretching eye mold, movable water-pipe connectors are installed above. These connectors are designed not to interfere with the threading operation.

5. The automatic correction control system is capable of adjusting the tension based on the diameter of the outlet line.

6. The 70W belt-driven synchronous motor features a stable wiring configuration and a rapid response speed.

| Model: | 24VD |

| Quantity of drawing dies: | 24 |

| Inlet diameter: | 0.15-0.45mm |

| Outlet diameter: | 0.03-0.12mm |

| Slip ratio of main machine: | 9% |

| Slip ratio of last die: | 6% |

| Max. Drawing speed: | 2000m/min |

| Using motor/ main motor: | 5.5kw |

| Usage: | Bare copper wire drawing |

| Annealing method: | DC three section annealing |

| Voltage: | 380V or Customized |

| Brake: | Pneumatic brake |

| Correction system: | Automatically control |

| Colour: | As customer's need |

| Brand: | Liqiang or OEM |

| Operation direction: | Right hand machine |

中文简体

中文简体 русский

русский Español

Español عربى

عربى