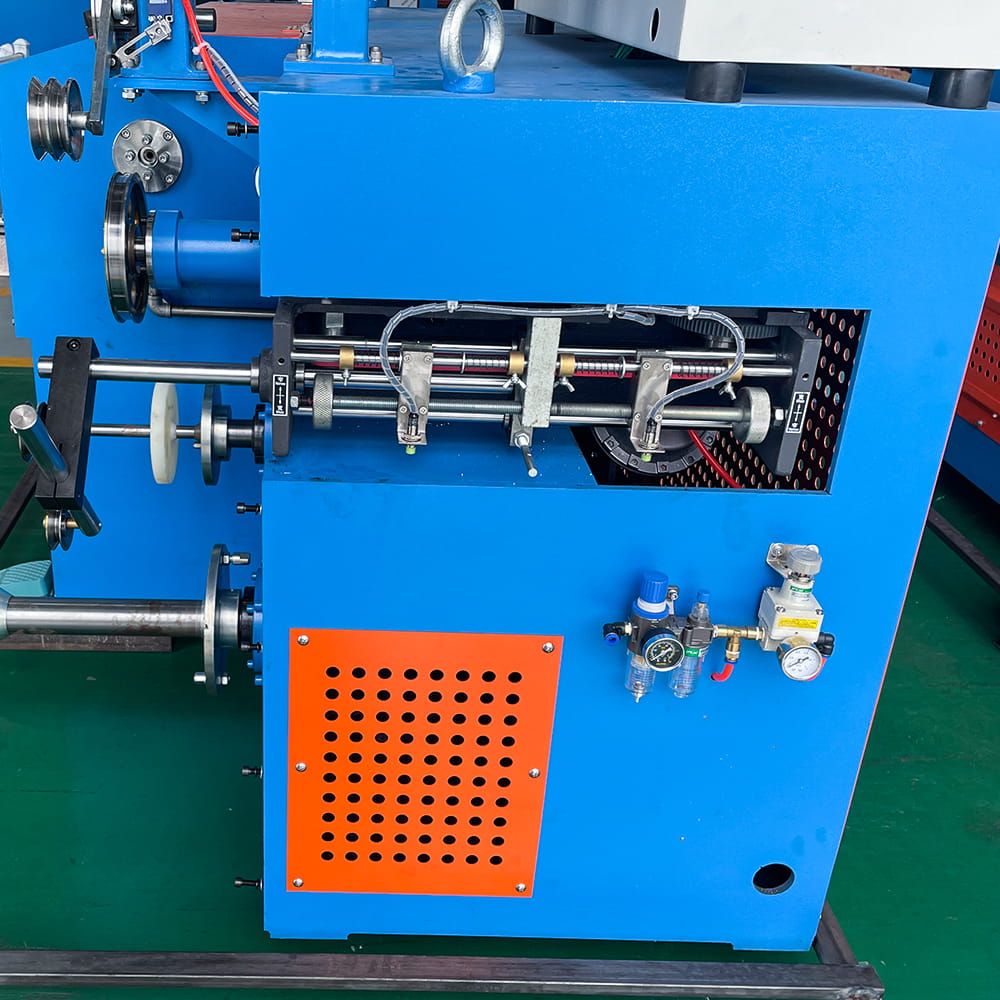

1. The machine features a full-immersion lubrication system and synchronous-belt drive, offering characteristics such as constant tension, low noise, and high efficiency.

2. The capstan is made of special tool - steel material.

3. The equipment is equipped with PLC control, double-motor and double-frequency - conversion technology, and a color touch-screen display.

4. A special straightening device is added to the export die, facilitating the release and annealing of the finished - product wire in the subsequent process.

5. A stepper motor is employed for wire arrangement, enabling adjustable and smooth wire-laying.

| Model: | 24DBX-H |

| Inlet diameter: | Φ0.8-1.2mm |

| Outlet diameter: | Φ0.2 mm ~Φ0.25mm |

| Max. annealing speed: | 1500m/min |

| Drawing motor: | 11KW DC |

| Final capstan motor: | 75KW DC |

| Diameter of drum: | Φ450mm |

| Take up bobbin: | PND500/630 |

| Max. drawing dies: | 24 |

| Capstan: | Bearing steel |

| Frame: | Cast |

| Correction system: | Automatically control |

| Dynamic control: | Double frequency converters control |

| Transmission method: | Timing belt |

| Lubrication system of drawing: | mmersing+spray type |

| Suitable spool: | As per customer's requirement |

中文简体

中文简体 русский

русский Español

Español عربى

عربى