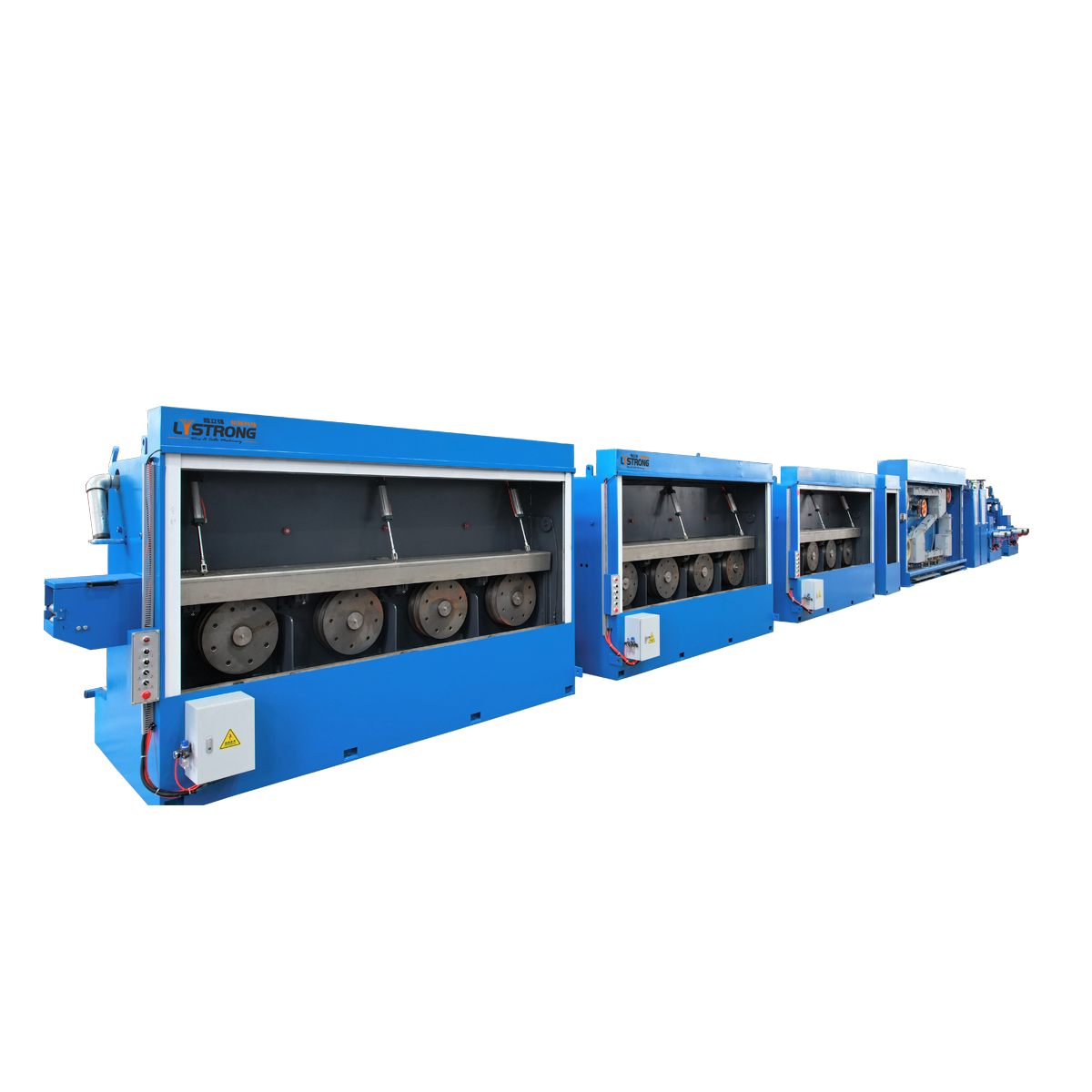

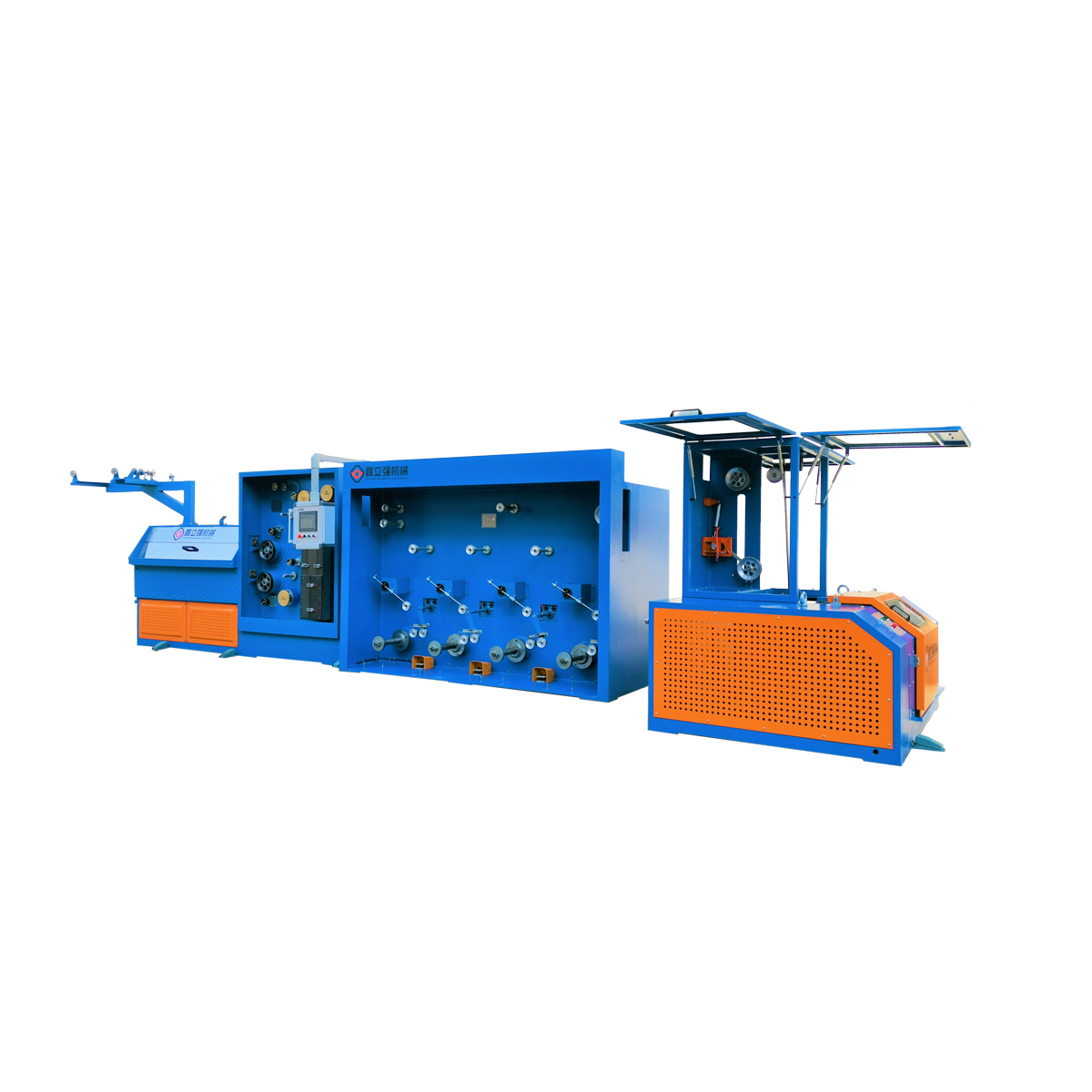

In the ever-evolving landscape of industrial manufacturing, optimizing production processes is paramount to staying competitive and meeting customer demands. One such innovation that has gained prominence is the Wire Cable Bunching Machine, designed to twist multi-strand bare copper and tinned wires efficiently. A common question among industry professionals is whether this machine can seamlessly integrate into existing production lines.

Compatibility Assessment

The first step in integrating the

Wire Cable Bunching Machine into an existing production line is assessing its compatibility. This involves evaluating factors such as:

Size and Space Requirements: Determine whether the machine can fit into the available space within the production facility without disrupting other operations.

Output Capacity: Ensure that the machine's output capacity aligns with the production requirements of the existing line to prevent bottlenecks or overcapacity issues.

Wire Types and Sizes: Confirm that the Wire Cable Bunching Machine can handle the types and sizes of wires used in the existing production process.

Workflow Integration

Integrating the Wire Cable Bunching Machine seamlessly into the workflow of the existing production line is crucial for maintaining efficiency. Considerations include:

Positioning: Identify the optimal location within the production line where the machine can be placed to streamline the workflow and minimize material handling.

Material Flow: Analyze how the introduction of the

Wire Cable Bunching Machine affects the flow of materials and processes within the production line to ensure smooth operation.

Automation Compatibility: If the existing production line is automated, ensure compatibility between the Wire Cable Bunching Machine and existing control systems for seamless integration.

Training and Familiarization

Providing adequate training to operators and staff is essential for successful integration. Key aspects include:

Operation Training: Train operators on how to operate the Wire Cable Bunching Machine effectively, including setup, programming, and troubleshooting.

Maintenance Procedures: Educate maintenance personnel on the maintenance requirements of the machine to ensure optimal performance and longevity.

Production Planning and Optimization

Integrating the Wire Cable Bunching Machine into production planning processes is vital for maximizing its benefits:

Scheduling: Incorporate the machine into production schedules to optimize workflow and minimize downtime.

Quality Control: Implement quality control measures to ensure that the integrated machine meets quality standards and produces consistent, high-quality output.

中文简体

中文简体 русский

русский Español

Español عربى

عربى

Contact Us