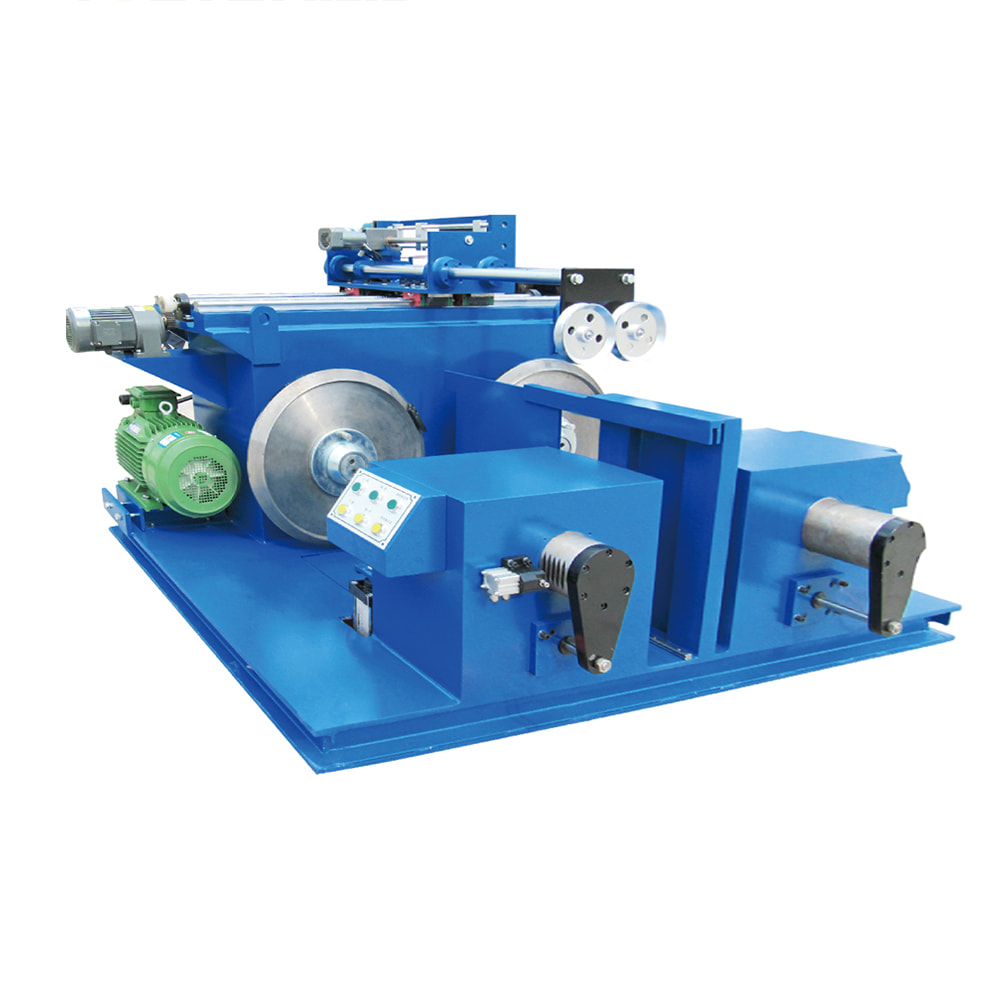

Steel wire drawing machines play a pivotal role in various industries, facilitating the production of high-quality wire for diverse applications. While these machines are essential for manufacturing processes, it's crucial to examine their environmental impact, particularly concerning noise levels and emissions.

One significant environmental consideration associated with steel wire drawing machines is noise emissions. The operation of machinery, especially in industrial settings, can generate considerable noise levels. Within a steel wire drawing machine, numerous components contribute to noise production, including the motor, gears, and the wire being drawn through dies.

The noise generated by these machines can have several implications. Firstly, it affects the comfort and well-being of operators working in close proximity to the equipment. Prolonged exposure to high noise levels can lead to hearing loss and other health issues, highlighting the importance of implementing measures to mitigate noise emissions.

Furthermore, excessive noise can disrupt the surrounding environment, impacting nearby workers, residents, and wildlife. Industrial noise pollution also poses challenges for regulatory compliance, as many jurisdictions have established limits on acceptable noise levels in workplaces and communities.

To address noise emissions, manufacturers of steel wire drawing machines employ various strategies. These may include incorporating sound insulation materials, implementing vibration dampening techniques, and designing enclosures to contain noise within the machine. Additionally, regular maintenance and lubrication of machine components can reduce friction and minimize noise generation during operation.

While emissions from

Steel wire drawing machines may not be as prominent as those from heavy machinery or industrial furnaces, certain processes involved in wire drawing can produce emissions or by-products. One potential source of emissions is the use of lubricants or coolants to facilitate the drawing process. If not properly managed, these substances may release volatile organic compounds (VOCs) into the air or wastewater, contributing to environmental pollution.

Additionally, the energy source powering the steel wire drawing machine can have implications for emissions. While electrically powered machines produce fewer direct emissions compared to those powered by fossil fuels, the environmental impact depends on the source of electricity. Utilizing renewable energy sources or implementing energy-efficient practices can help mitigate emissions associated with machine operation.

中文简体

中文简体 русский

русский Español

Español عربى

عربى

Contact Us