When evaluating rod breakdown machines for aluminum wire, one critical consideration is the orientation of the machine—whether horizontal or vertical. Both designs play pivotal roles in wire drawing processes, yet they each offer distinct advantages and operational characteristics that can significantly impact manufacturing efficiency and facility layout.

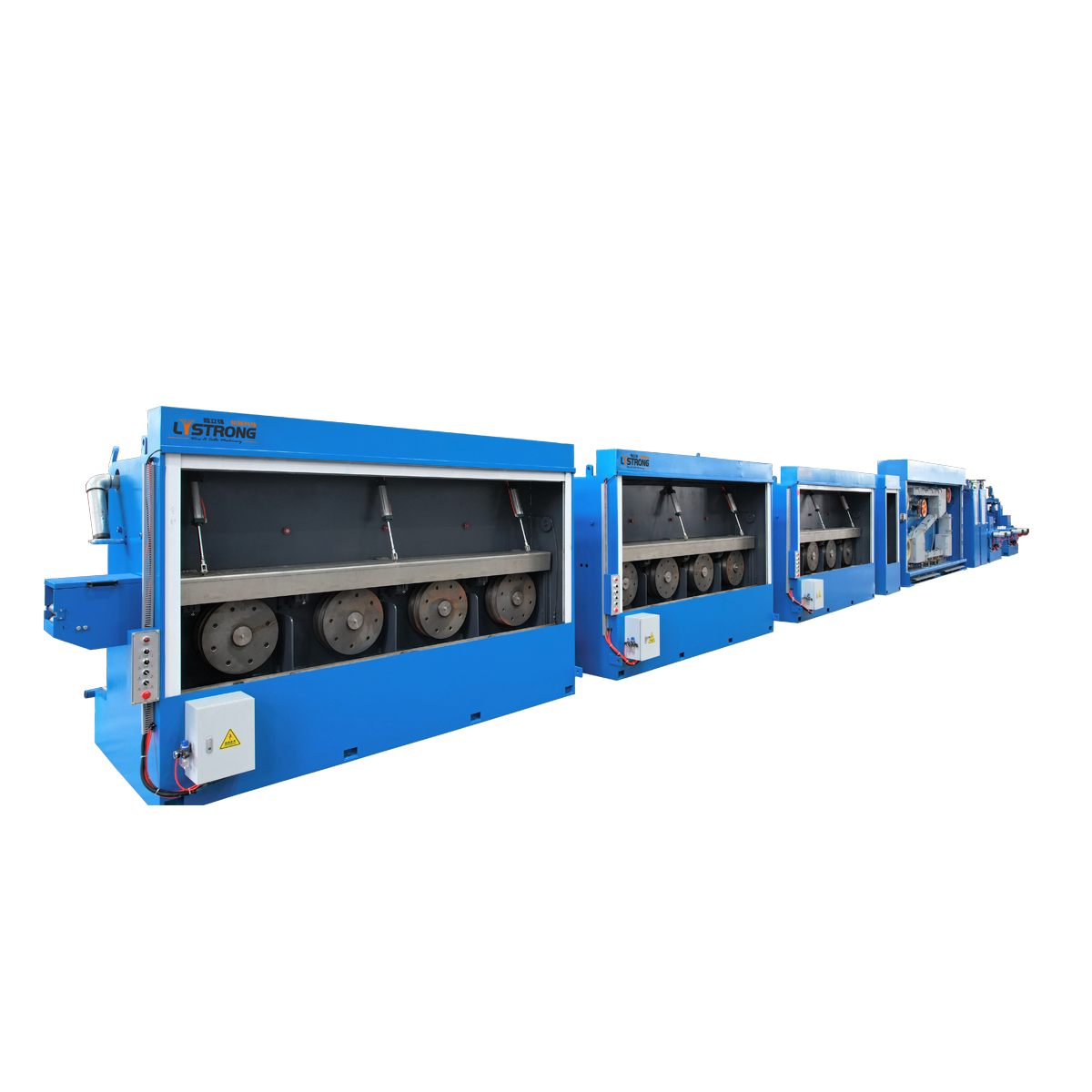

Horizontal rod breakdown machines are designed with a horizontal layout, where the wire rod is fed and drawn parallel to the ground. This design inherently requires more floor space due to its length. The horizontal orientation facilitates easier access for operators and maintenance personnel, simplifying routine upkeep and reducing downtime. The machine’s components are arranged at a more accessible height, which often makes routine maintenance and repairs less cumbersome and more efficient. Furthermore, the horizontal layout supports straightforward handling of long rods or coils, which can simplify the loading and unloading processes. This design is particularly advantageous in larger facilities where floor space is not a limiting factor, and the straightforward access enhances operational efficiency.

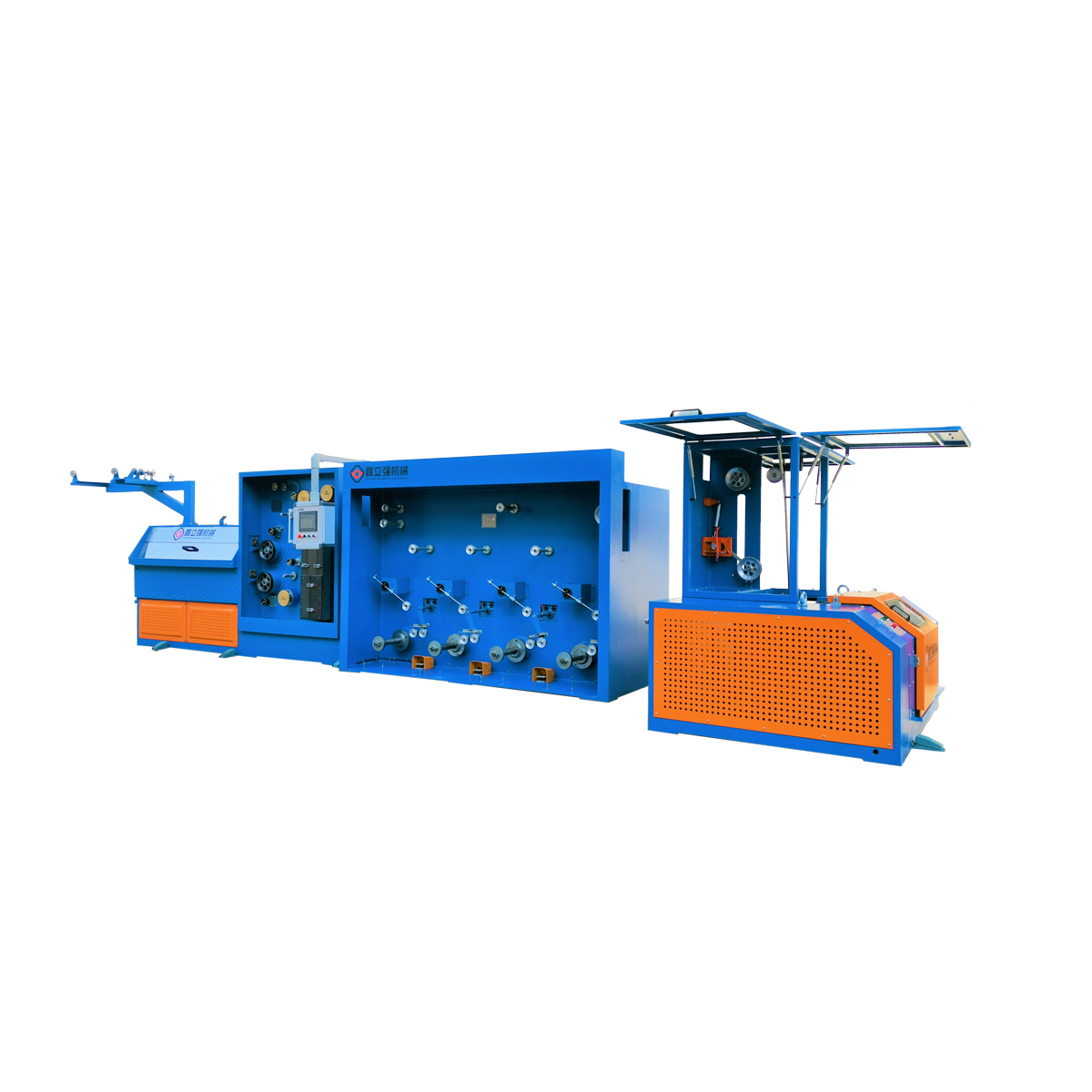

In contrast, vertical rod breakdown machines are oriented to feed and draw the wire rod in a vertical direction. This vertical arrangement results in a more compact footprint, which can be particularly beneficial in facilities with limited floor space. The design leverages gravity to aid in the wire drawing process, which can enhance performance in specific applications. However, maintenance can be more challenging, as accessing components that are positioned high up might require specialized equipment or procedures. Despite this, the vertical machine’s compact nature allows for a streamlined integration with other vertical equipment in a production line, potentially optimizing space usage and operational flow.

Both types of machines offer significant benefits, particularly in the context of aluminum wire production. Horizontal machines, with their ease of maintenance and handling, are often chosen for their operational simplicity and efficiency in larger production environments. Vertical machines, while potentially more challenging in terms of maintenance, are prized for their space efficiency and ability to leverage gravity in the drawing process. These machines are equipped with advanced features such as automatic tension control systems and PLC (Programmable Logic Controller) with HMI (Human-Machine Interface) to enhance control and efficiency, making them well-suited to meet varying production needs.

Ultimately, the choice between horizontal and vertical rod breakdown machines depends on a range of factors, including facility layout, maintenance preferences, and production requirements. Understanding these differences helps manufacturers select the most appropriate machine for their specific needs, ensuring optimal performance and efficiency in aluminum wire processing.

中文简体

中文简体 русский

русский Español

Español عربى

عربى

Contact Us