1. It is driven by highly precise helical gears and features a special oil - lubrication mechanism, with dual-motor drive.

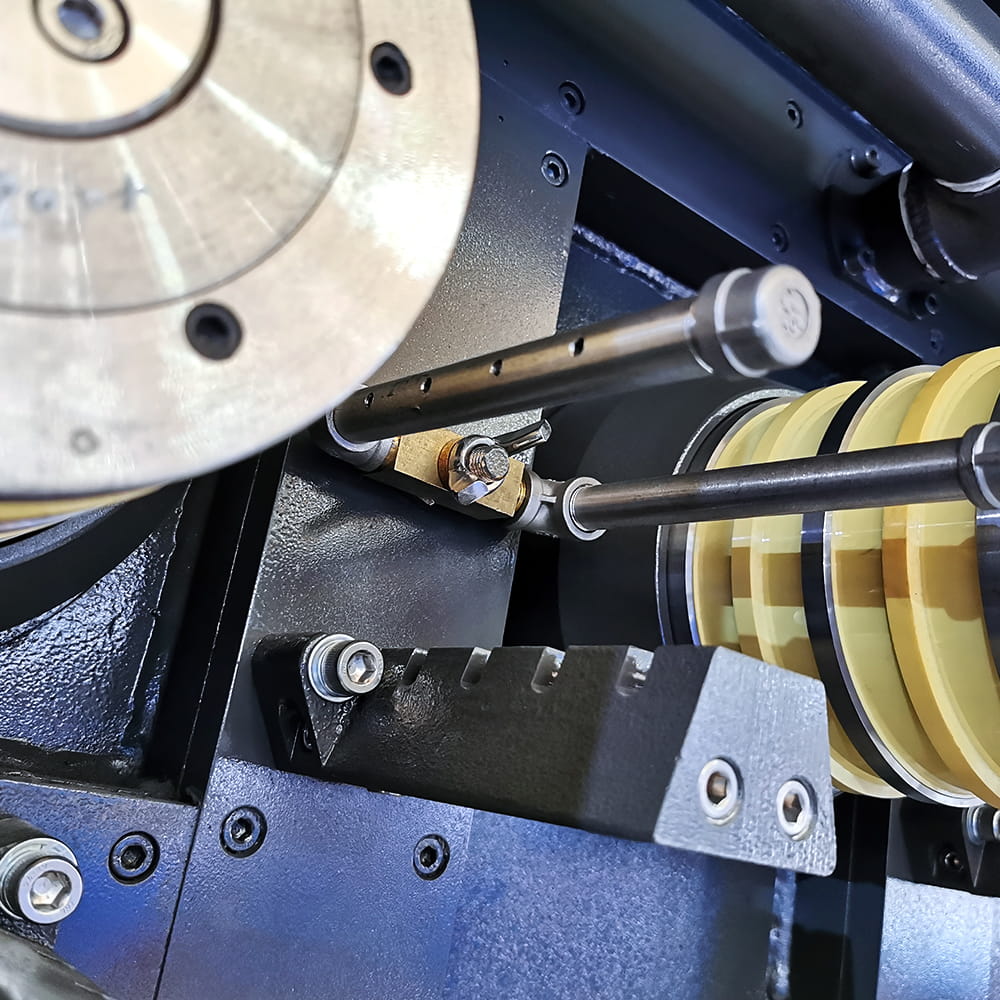

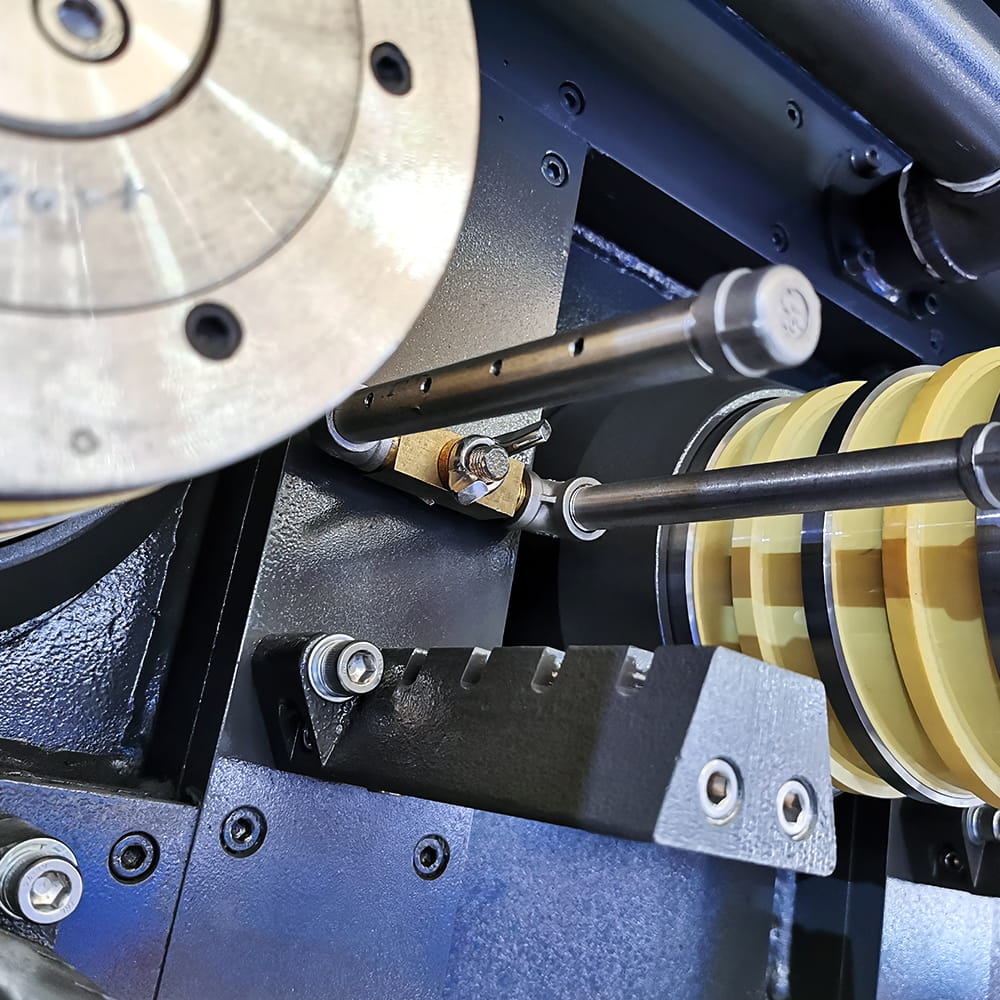

2. The capstan and die lubrication system adopts an emulsion-spraying method with an internal-force-generating design within the die holder. This design not only provides more sufficient lubrication but also saves space and makes operation more convenient.

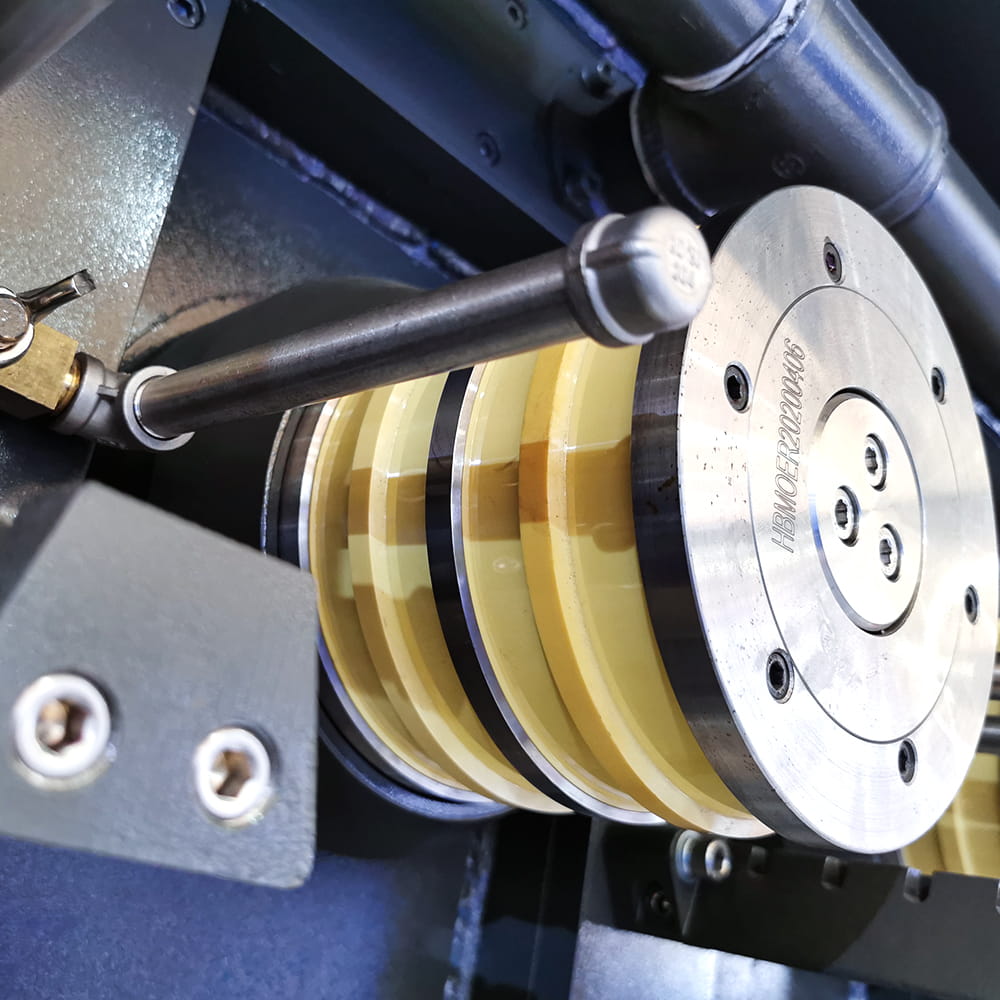

3. The annealing contact copper rings and nickel tubes are made of special alloys, ensuring a longer service life.

| Model: | 25-4DT |

| Usage: | Bare copper wire drawing |

| Inlet diameter: | 4*Φ1.5mm-Φ2.0mm |

| Outlet diameter: | 4*Φ0.15mm-Φ0.5mm |

| Quantity of drawing dies: | 25 |

| Slip ratio of main machine: | 16% |

| Slip ratio of last die: | 8% |

| Correction system: | Automatically control |

| Max. Drawing speed: | 1800m/min |

| Using motor/ main motor: | 55KW+18.5KW |

| Dynamic control: | Double frequency converters control |

| Operation direction: | Right hand machine |

| (from Left to right) | |

| Colour: | As customer's need |

| Brand: | Liqiang or OEM |

| Voltage: | 380V or Customized |

| Brake: | Pneumatic brake |

中文简体

中文简体 русский

русский Español

Español عربى

عربى