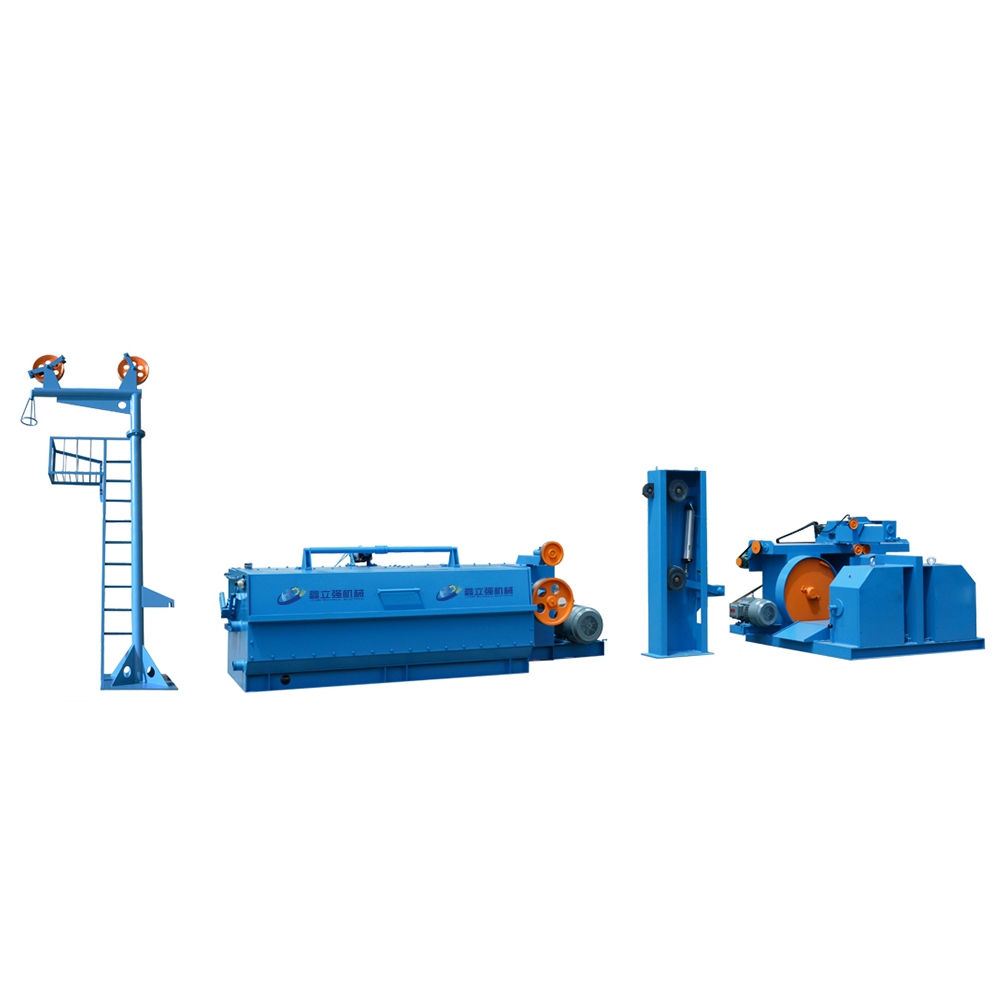

Whether you’re producing high-conductivity electrical cables or robust structural reinforcements, the performance of your Aluminum Wire Rod Breakdown Machines can make or break your operation—literally. These machines are not one-size-fits-all; their ability to adapt to different applications is what sets them apart in the competitive world of wire drawing. Let’s explore how these machines shine in two distinct yet equally demanding fields: electrical conductivity and structural reinforcement, and why they’re indispensable for modern manufacturers.

In the electrical industry, where precision and consistency are paramount, machines designed for breaking down aluminum rods must deliver wires with exceptional conductivity and flawless surface finishes. Aluminum is a popular choice for electrical cables due to its lightweight nature and excellent conductive properties, but achieving the desired thinness (down to 1.5mm) without compromising quality requires a machine that’s both precise and reliable. This is where advanced features like automatic tension control and PLC integration come into play. For instance, when drawing aluminum wire for high-voltage transmission lines, even the slightest variation in diameter can lead to inefficiencies or failures. The horizontal design of these machines, combined with their low-slip operation, ensures that every inch of wire meets stringent industry standards. Additionally, the ability to switch between single and double spoolers allows manufacturers to optimize production for large-scale electrical projects, ensuring uninterrupted supply chains and consistent output.

On the flip side, when it comes to structural reinforcement, the demands on aluminum rod breakdown equipment shift significantly. Here, the focus is less on conductivity and more on tensile strength and durability. Aluminum wires used in construction often need to withstand significant stress, whether they’re embedded in concrete or used as part of scaffolding systems. To meet these requirements, manufacturers may need to process harder aluminum alloys or adjust the machine settings to accommodate thicker wire diameters. Fortunately, modern breakdown machines are equipped with customizable dies and rollers that can handle a variety of materials and sizes. For example, if you’re working with an aluminum alloy that has higher tensile strength, the machine’s robust cast iron body ensures stability during the drawing process, while its belt transmission system minimizes wear and tear. This adaptability makes it possible to produce wires that are strong enough for structural applications without sacrificing the efficiency needed for large-scale production.

But what happens when you need to balance both industries? Many manufacturers serve multiple sectors, requiring their Aluminum Wire Rod Breakdown Machines to be as versatile as possible. This is where customization becomes a game-changer. Some machines can be retrofitted with additional sensors or upgraded software to monitor material properties in real time, ensuring that the output meets the specific needs of each application. For instance, if you’re switching from producing soft aluminum wires for electrical use to harder alloys for construction, the machine’s HMI interface allows operators to quickly adjust parameters like speed, tension, and die pressure. This flexibility not only saves time but also reduces material waste, making the entire process more cost-effective and sustainable.

Beyond adaptability, another critical factor is the machine’s ability to maintain consistent performance across different materials and applications. Whether you’re drawing aluminum rods for electrical cables or structural reinforcements, the last thing you want is inconsistent coiling or uneven tension. That’s why many modern machines come equipped with automatic correction systems that ensure smooth winding regardless of the wire’s diameter or material properties. This feature is particularly valuable when processing softer aluminum alloys, which are prone to deformation if not handled correctly. By maintaining uniform tension throughout the coiling process, these machines help prevent defects that could compromise the wire’s performance in its final application.

中文简体

中文简体 русский

русский Español

Español عربى

عربى

Contact Us