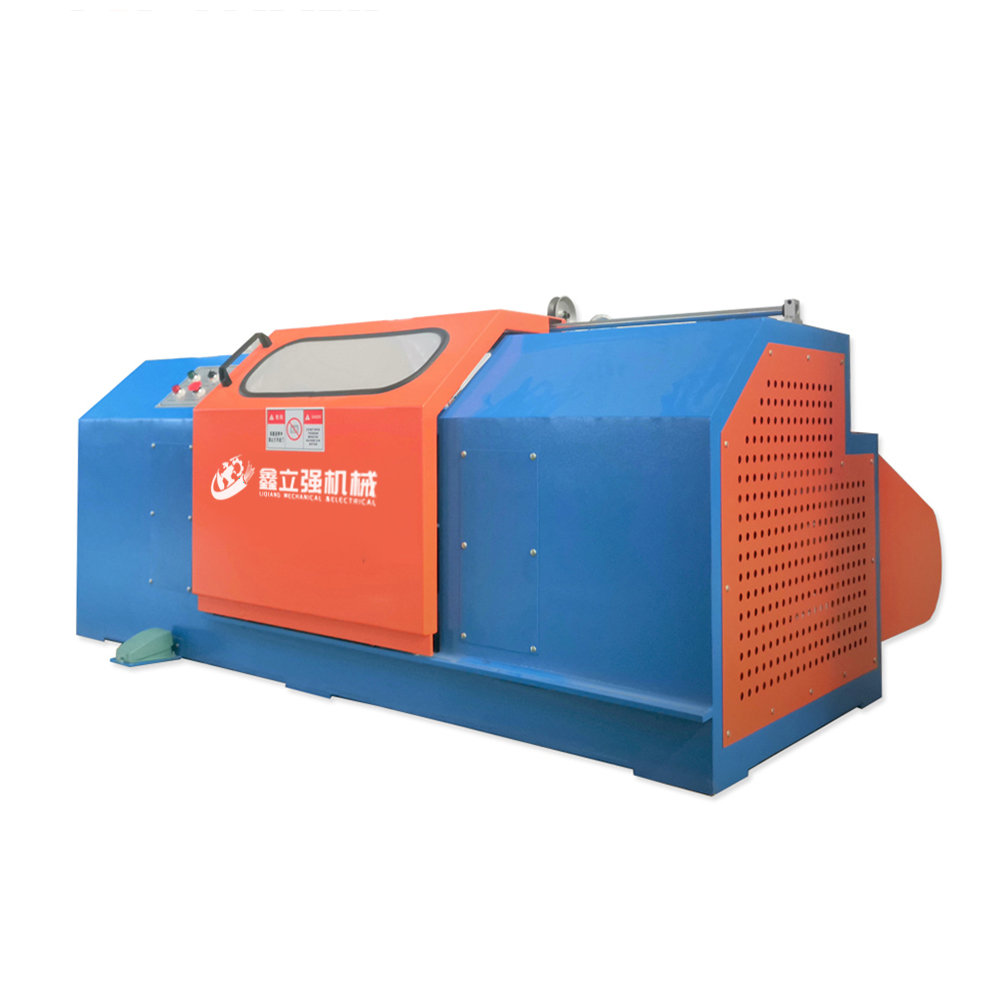

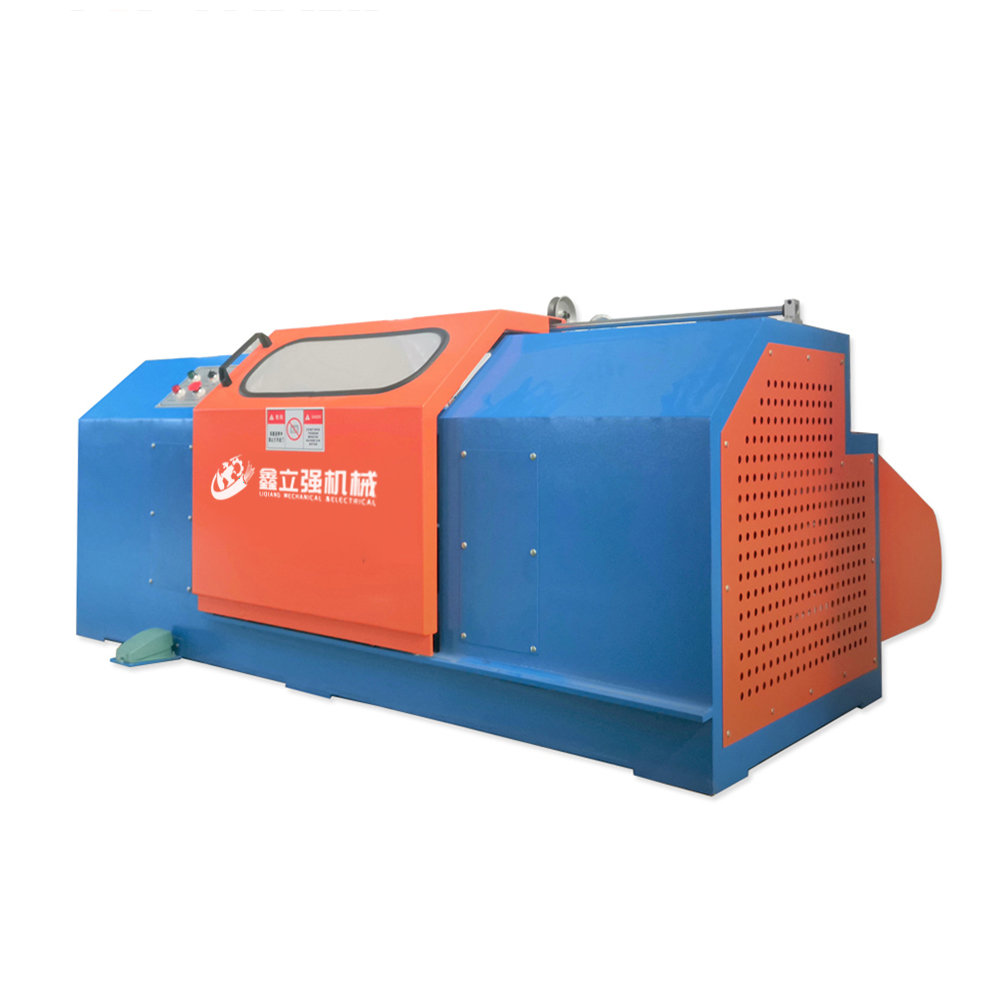

The Automatic Wire Take-up Machine is designed with versatility in mind, making it a powerful tool for industries that deal with various wire types, such as copper, steel, aluminum, and brass. One of the most common questions surrounding this machine is whether it can accommodate wires of these different materials simultaneously or if specific setup adjustments are required for each wire type. The answer lies in the machine's adaptability, thanks to its advanced design and engineering features.

While the machine is capable of handling a wide range of wire materials, it does require some setup adjustments to ensure optimal performance for each wire type. For example, copper and aluminum wires, being softer and more flexible, may require different tension settings and coiling speeds compared to steel and brass wires, which are typically harder and more rigid. The machine allows operators to easily adjust parameters such as tension control, coiling speed, and winding pressure, enabling seamless transitions between wire materials. However, these adjustments need to be done manually or through automated presets based on the material being processed. This ensures that each wire type is coiled with the right amount of force and precision, preventing issues like slippage, tangling, or damage to the wire.

The machine is equipped with imported electrical components that contribute to its high-speed coiling capabilities and stable operation. These components ensure that the machine can maintain consistent performance, even when switching between different wire materials. Its ability to smoothly handle various wire types is a result of careful engineering, where each material’s unique properties are considered to optimize the coiling process. Steel wires, for instance, may require stronger tension control due to their stiffness, while copper and aluminum can benefit from a more relaxed setting. The user-friendly interface allows operators to adjust settings quickly, reducing downtime when switching between different materials.

Another important aspect to consider is the machine’s coiling capacity. It is designed to handle large volumes of wire, making it ideal for industries that deal with high production rates. However, as the wire type changes, the machine’s coiling capacity might slightly shift, depending on the material’s flexibility and coil diameter. While copper and aluminum coils tend to be lighter and more compact, steel and brass coils may require additional space due to their heavier and more rigid nature. Therefore, some fine-tuning is necessary, but these adjustments are minimal and quick to perform.

In terms of overall efficiency, the Automatic Wire Take-up Machine provides a robust solution for manufacturers who work with a variety of wire materials. It’s not necessary to overhaul the entire setup for each material; rather, small adjustments are sufficient to accommodate copper, steel, aluminum, and brass wires. The machine’s low-noise operation, easy maintenance, and environmentally friendly design make it a cost-effective and sustainable choice for industries that require high-speed, high-volume wire coiling.

While the Automatic Wire Take-up Machine does not automatically switch between materials without adjustments, its flexibility and ease of use make it highly capable of handling different wire types. With proper setup, it ensures optimal coiling performance for copper, steel, aluminum, and brass wires, giving operators the confidence that their production process will remain efficient and smooth regardless of the material being processed.

中文简体

中文简体 русский

русский Español

Español عربى

عربى

Contact Us