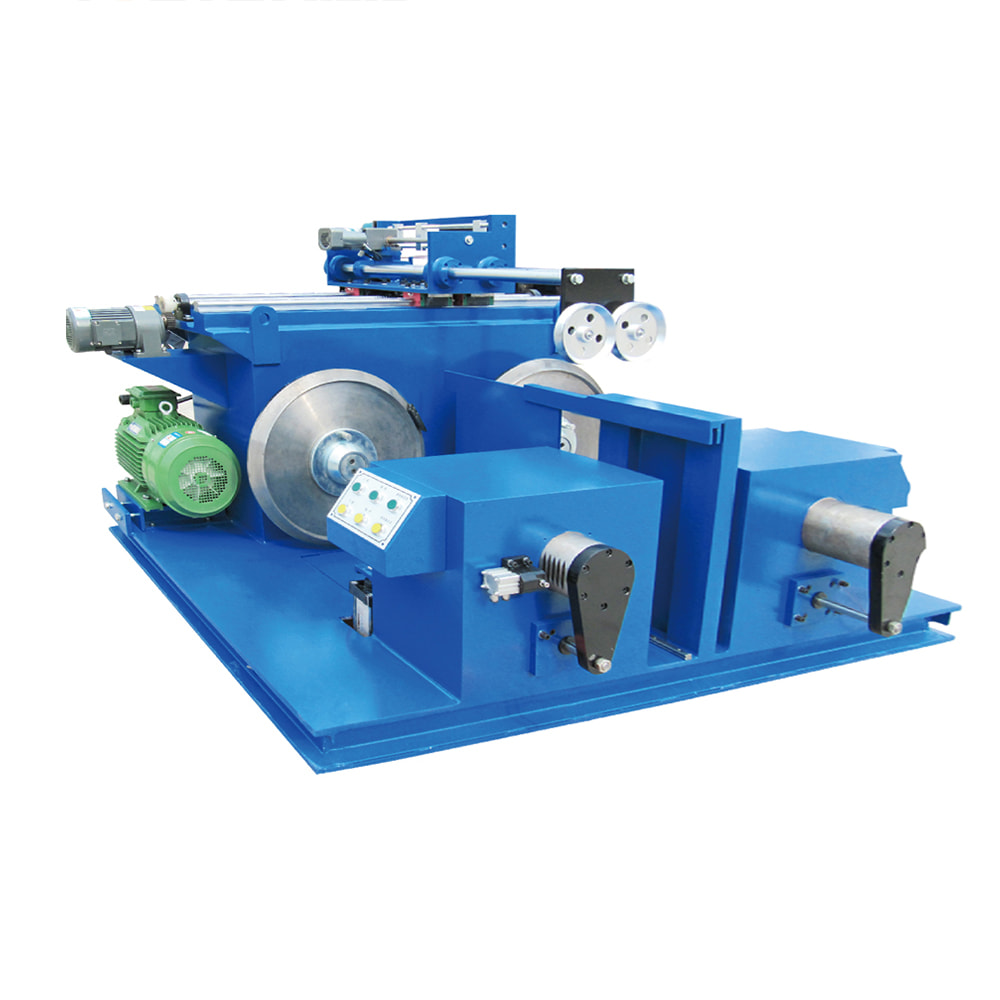

9DS Medium Copper wire drawing machine system line

Cat:Copper Wire Drawing Machines

This type of wire drawing machine is a high-speed model meticulously developed, designed, and manufactured after assimilating advanced foreign technol...

See DetailsThe Automatic Wire Take-Up Machine is designed to handle wire coiling with remarkable precision and care, ensuring that wire quality remains top-notch throughout the process. Whether working with copper, steel, aluminum, or brass wire, the machine incorporates several key features that prevent common issues like tangling, breakage, and inconsistent coiling, which are critical concerns for businesses that need to maintain high-quality wire production.

One of the primary ways the machine ensures wire quality is through its advanced tension control system. This system regulates the tension of the wire as it’s being coiled, ensuring that the wire does not become too tight or too slack, both of which can lead to damage or poor coil formation. By maintaining consistent tension, the machine prevents wire breakage and ensures that each coil is tight, uniform, and ready for use. This feature is particularly important for materials like copper or aluminum, which are prone to deformation if handled incorrectly. The machine’s ability to maintain perfect tension throughout the coiling process allows manufacturers to produce coils with minimal risk of defects, ensuring high-quality output every time.

Another crucial element of the machine’s design is its smooth, uninterrupted wire feeding system. The machine is equipped with a specially designed feed mechanism that allows the wire to move seamlessly through the system without any jerks or disruptions. This smooth feed prevents tangling or knotting, a common problem in high-speed wire coiling. The machine's ability to handle wires of various materials and sizes with such precision further reduces the chances of any unwanted tangles or disruptions. By maintaining a smooth and controlled flow of wire, the machine ensures that each coil is wound evenly and without interference, which is vital for maintaining both wire quality and operational efficiency.

Additionally, the Automatic Wire Take-Up Machine incorporates features designed to enhance the durability and reliability of the coils. With its low-noise operation, the machine minimizes vibrations that could cause strain or damage to the wire during the coiling process. The quiet operation also contributes to a safer and more comfortable working environment, helping to reduce stress on both the machine and the operator. Moreover, the machine’s use of high-quality, imported electrical components ensures stable and smooth running, which helps prevent fluctuations that could lead to issues like wire breakage or inconsistent coiling. This attention to detail in both mechanical and electrical design ensures that the machine produces high-quality coils while minimizing downtime for maintenance or repair.

In terms of material protection, the Automatic Wire Take-Up Machine is designed with environmentally friendly paint, which not only ensures a safer, more sustainable product but also contributes to the overall durability of the machine. This coating helps protect the machine from wear and tear over time, ensuring that the wire coiling process remains smooth and free of complications, even with frequent use.

Ultimately, the Automatic Wire Take-Up Machine is built with advanced features that ensure the highest quality wire coiling. From precise tension control to smooth wire feeding and durable construction, the machine offers a reliable solution for manufacturers looking to reduce the common issues of tangling, breakage, and inconsistent coil formation. By investing in this machine, businesses can achieve consistent, high-quality wire coils, ensuring that their products meet the highest industry standards.

Contact Us